Heat Transfer laboratory provides fundamental and industrial knowledge about modes of heat transfer, like conduction, convection and radiation, and their application. Heat Transfer Lab consists of the following equipment. Pin Fin Apparatus: This setup is designed to study the heat transfer in a pin fin. It consists of cylindrical fin fitted to the base in a rectangular duct. A blower is provided on one side of the duct to conduct experiments under forced convection heat transfer mode. Five thermocouples are embedded along the axis of the cylindrical fin at five different locations and one thermocouple placed in the air stream at the exit of the test section to measure the outlet air temperature. Digital Temperature Indicator is provided to read temperatures distribution along the fin. Test pipe is connected to the delivery side of the blower along with the Orifice to measure the flow of air through the pipe. A heater heats one end of fin and heat flows to another end. Heat input to the heater is given through variac. Students will be expected to develop the following skills/understanding upon the successful completion of this experiment.

Equipment

- Pin Fin Apparatus

- Extended surface

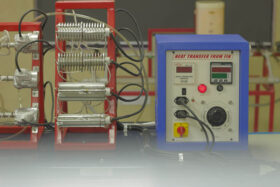

- Heat transfer service unit

- Emissivity measurement apparatus

- Heat transfer in natural convection

- To determine the thermal conductivity of a metallic rod.

- To determine the thermal conductivity of an insulating power.

- To determine the thermal conductivity of a solid by the guarded hot plate method.

- To find the effectiveness of a pin fin in a rectangular duct natural convective condition and plot temperature distribution along its length.

- To find the effectiveness of a pin fin in a rectangular duct under forced convective and plot temperature distribution along its length.

- To determine the surface heat transfer coefficient for a heated vertical tube under natural convection and plot the variation of local heat transfer coefficient along the length of the tube. Also, compare the results with those of the correlation.

- To determine average heat transfer coefficient for an externally heated horizontal pipe under forced convection & plot Reynolds and Nusselt numbers along the length of pipe. Also, compare the results with those of the correlations.

- To measure the emissivity of the gray body (plate) at different temperature and plot the variation of emissivity with surface temperature.

- To find overall heat transfer coefficient and effectiveness of a heat exchanger in parallel and counterflow conditions. Also, plot the temperature distribution in both the cases along the length of the heat of heat exchanger.

- To verify the Stefen-Boltzmann constant for thermal radiation.

- To demonstrate the super thermal conducting heat pipe and compare its working with that of the best conductor i.e. copper pipe. Also plot temperature variation along the length of time or three pipes.

- To study the two phases heat transfer unit.

- To determine the waterside overall heat transfer coefficient on a cross-flow heat exchanger.

- Design of Heat exchanger using CAD and verification using thermal analysis package eg. I-Deas etc.

In this lab the students learn the complicated phenomenon of heat transfer with the help of apparatus like parallel and counter flow heat exchanger, composite wall, lagged pipe, apparatus for measuring heat transfer properties under natural and forced convection, heat pipe demonstrator and pin fin performance apparatus, dropwise / filmwise condensation, two-phase heat transfer unit.