This lab contains strain gauge cantilever beam kit, load cell, LVDT, RTD, thermocouple kit, capacitive, inductive, photoelectric pickup kit and dead weight pressure gauge tester, measurement of the level by capacitance method, calibration of bimetallic thermometer, pressure & temperature control trainer.

Transducer is a device which converts one form of energy into another form like Electrical to Mechanical, Mechanical to Electrical, Thermal to Electrical and etc, Emphasis in the instrumentation trainers will be directed toward electronic instrumentation systems rather than mechanical systems. In most cases electronic systems provide better data more accurately completely characterize the

design or process being experimentally evaluated. Also the electronic system provides an electrical out put signal that can be used for automatic data reduction or for the control of the process. These advantage of the electronic measurement system over the mechanical measurement system have initiated and sustained trend instrumentation toward electronic methods. An attempt is made through these “Instrumentation trainer kits” to make as easy as possible for the students to learn about the electronic instrumentation system and various transducers used for the measurement of mechanical

component. The instrumentation tutor panels are design in such a way that block diagrams of the stages of electronic instrumentation system are clearly pictured on them. This makes the instrumentation tutor self-explanatory and also the best teaching aid for engineering students. Since the instrumentation tutors are not instrument as a whole the accuracy of the measurement cannot be claimed. It is very clear that the instrumentation tutors are only for demonstration purpose and cannot be used for any external measurement other than conducting experiments.

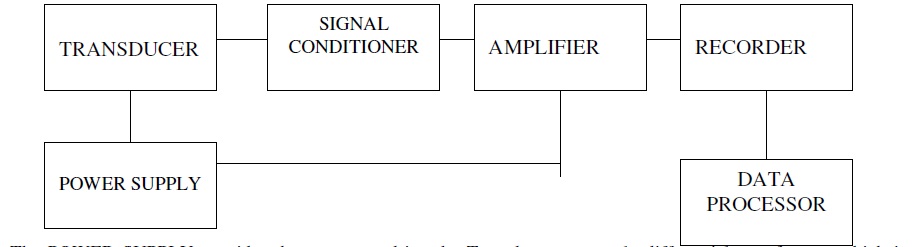

The complete electronic instrumentation system usually contains six subsystems or elements of the TRANSDUCER is a device that converts a change in the mechanical or thermal quantity being measured by a change of an electrical quantity. Example strain gauges bonded into a specimen gives out electrical output by changing its resistance when the material is strained.

The POWER SUPPLY provides the energy to drive the Transducers, example differential transformer, which is a transducer used to measure displacement required an AC voltage supply to excite the coil.

SIGNAL CONDITIONERS are electronic circuits the convert, compensate, or manipulate the output from into a more usable electronic quantity. Example the whetstone bridge used in the strain transducer converts the change in resistance. AR to a change in the resistance AE. AMPLIFIERS are required in the system when the voltage output from the transducer signal conditioner combination is small. Amplifiers with a game of 10 to 1000 are used to increase their signals to levels they are compatible with the

voltage – measuring devices. RECORDERS are voltage measuring devices that are used to display the measurement in a form that can be read and interpreted Digital/Analog voltmeters are often used to measure static voltages. DATA PROCESSORS are used to convert the output signals from the instrument system into data that can be easily interpreted by the Engineer. Data processors are usually employed where a large amount of data are being collected and manual reduction of these data would be too time-consuming and costly.